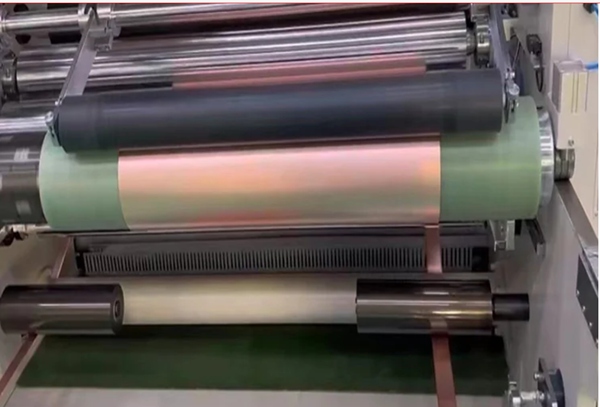

FRP composite core tube (shaft)

The FRP composite material core tube (shaft) used for optical thin film, copper foil, and aluminum foil winding is made by impregnating high-strength wear-resistant glass fiber with epoxy resin matrix on a four-dimensional CNC winding machine. According to the specifications, models, and dimensions required by the user, the glass fiber filament is wound at a certain angle on the steel winding core mold (calculated and designed according to the laying theory) to achieve better mechanical performance requirements. It is heated and rotated to wind to the set thickness, After secondary heating and solidification, it is then turned to the core tube (shaft) required by the customer's drawings. Used for rolling various optical films, copper foils, and aluminum foils, it is the preferred new material for optical film manufacturing, copper foil manufacturing, and aluminum foil manufacturing enterprises.

CN

CN English

English