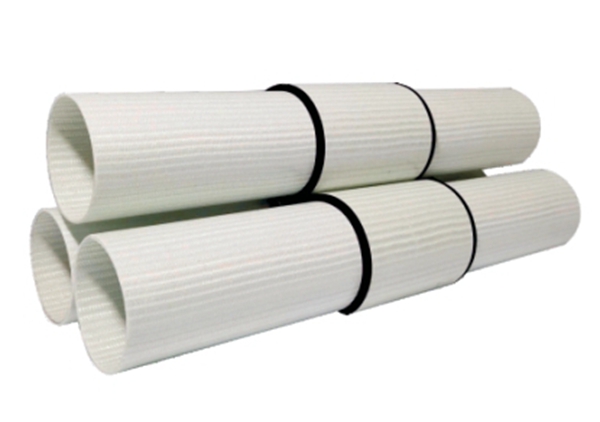

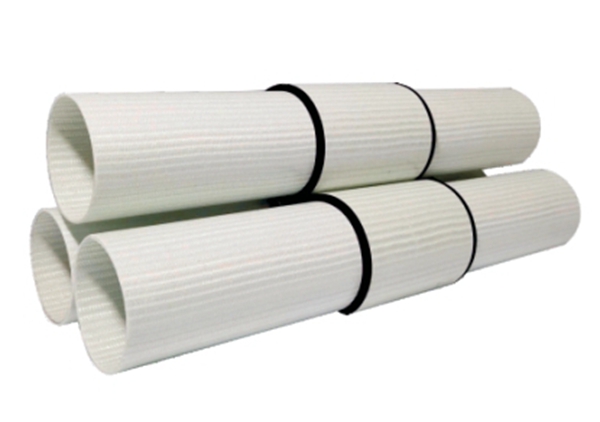

BWFRP fiber reinforced cable protective tube

Taporel's BWFRP cable protection tube (pipe) has a unique production process with high technical content. It has a three-layer structure through an online complete winding pultrude molding process. The inner and outer layers are both cross-braided layers, and the middle layer is annular and longitudinal performance. The multi-dimensional braided structure makes the inside and outside of the pipe texture composite reinforced layer. As the supporting pipe skeleton, the fiber direction determines the product clear and uniform, and every place is stressed evenly against pressure, which greatly improves the ring stiffness and toughness of the pipe and has better impactresistance.

CN

CN English

English