The use of epoxy fiberglass wound tube. Installation is divided into machine installation and manual installation.

Machine installation requires equipment similar to the hose and water cloth winding machine.

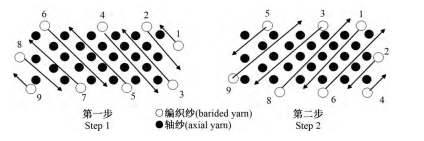

Manual installation is briefly described as below:

1.After winding one end of the hose (wires and cables), the epoxy fiberglass winding tube is positioned at the joint of the hose (wires and cables). After positioning, reverse the spiral protective sleeve and loosen it. You can move it freely and start to rotate from the wrapped middle part to the other end.

2.Wrap the middle part of the hose (wires, cables) around the middle part of the epoxy fiberglass winding tube, starting from the wound middle part and winding towards one end of the hose (wires, cables).

3.Wrap both ends of the epoxy fiberglass winding tube around the outside of the hose (wires, cables) to complete the installation of the fiberglass winding tube.

[Application fields of epoxy fiberglass wound tube] It is widely used in high-voltage electrical appliances such as oil-immersed transformers, H-class dry-type transformers, railway locomotive transformers, tap-changers, reactors, arresters, SF-6 transformers, experimental equipment, etc. The main insulation of the high voltage product has the advantages of high voltage resistance, small dielectric loss, low partial discharge, high mechanical strength, no deformation, low water absorption, and chemical corrosion resistance.

CN

CN English

English