High Ring Rigidity, Impact Resistance,Anti-settling

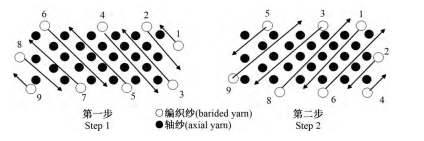

Compared with traditional tubes, BWFRP tubes are pultruded through interweaving high-performance fiber patterns and longitudinal interweaving, which improves the ring stiffness of the tubes physically and can resist damage caused by external heavy pressure and foundation settlement.

Corrosion Resistance,High Water Resistance

BWFRP tubes are extruded under high temperature and high pressure. The product has high density and excellent water resistance. It uses high-performance epoxy resin and alkali-free glass fiber raw materials, and its acid and alkali resistance is higher than that of traditional tubes.

Safety and Environmental Protection

The main raw material of BWFRP tube comes from quartz stone (stone), and the raw material extracted from the stone is returned to the ground, which is completely in line with the laws of nature and has passed the strict environmental protection testing standards of the country and the European Union.

Easy to Transport and Install

The BEFRP tube adopts the straight-through continuous lifting method. The tube with the same wall thickness is lighter in weight, reduces trans portation pressure, is convenient to install, and greatly shortens the construction period. At the same time, avoid the long exposure time of road excavation, which will affect the urban traffic order.

Good High and Low Temperature Resistance

BWFRP tubes are frost-resistant and high-temperature resistant,and can adapt to harsh environments. BWFRP tubes will not be damaged or deformed under extreme temperatures of-50 degrees Celsius to 200 degrees Celsius, and still have high-quality, good toughness and extremely high strength.

Smooth Inner Wall.Convenient for Cable Insertion

The inner wall of the tube is smooth, and it is convenient to thread the cable. Rubber sealing rings are installed at the first two places of the joint to adapt to thermal expansion and contraction, effectively preventing sediment intrusion

Excellent Thermal Conductivity

Under the same ring stiffness, the BWFRP tube wall is the thinnest, with excellent thermal conductivity and better carrying capacity. Lower electrical losses increase cable life.

High Tensile Strength

The braiding angle of BWFRP tube reaches 120°, and adopts inner and outer three-layer braiding process, which has high tensile strength. Compared with traditional tubes, the flexibility performance has been greatly improved.

Excellent Flame Retardant

BWFRP tube has excellent flame retardant performance, the oxygen index is greater than 28, exceeding the national standard, and it will not be ignited at all when the tube is exposed to fire.

High Electrical Insulation

Using excellent alkali-free fiber and high-performance epoxy resin base to form under high pressure conditions, the density of BWFRP tubes is 35% higher than that of traditional tubes, withno bubbles and high insulation.

CN

CN English

English